Introduction

In CNC machining, accuracy is measured in microns and productivity is measured in minutes. Every second of downtime reduces profitability, while even the smallest setup error can cause costly scrap. Yet one of the most overlooked factors in machining success is not the tool, nor the cutting parameters—it is the workholding system. Self-centering vises have emerged as an indispensable solution for machinists who demand both efficiency and precision.

What Are Self-Centering Vises?

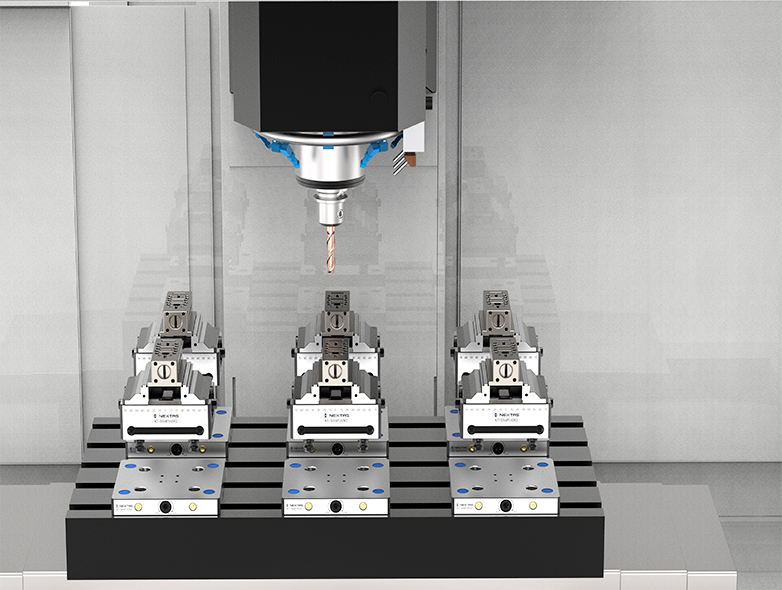

Unlike conventional vises, where a fixed jaw holds against a moving jaw, self centering vise move both jaws simultaneously toward the centerline. This ensures that the workpiece is always aligned with the center of the machine table. By removing the variability of manual alignment, they improve repeatability and speed up workflows.

Efficiency Gains

- Reduced Setup Times – Operators no longer need to measure and re-clamp workpieces manually. Centering is automatic.

- Faster Changeovers – Switching between part families can be done in minutes.

- Higher Throughput – With less time wasted on alignment, machines spend more time cutting.

Precision Gains

- Symmetrical Clamping – Equal jaw pressure reduces distortion on delicate or thin-walled parts.

- Micron Repeatability – The same part is positioned identically every time, ensuring consistent machining.

- Multi-Axis Advantage – In 4- and 5-axis machining, centered workpieces simplify toolpath programming.

Applications

- Aerospace: Complex, high-tolerance components.

- Medical Devices: Tiny implants and surgical tools.

- Automotive: Large-volume runs requiring repeatability.

Conclusion

Hydraulic vise are more than a convenience; they are a strategic investment. By simultaneously improving productivity and quality, they help manufacturers remain competitive in a fast-moving global market.